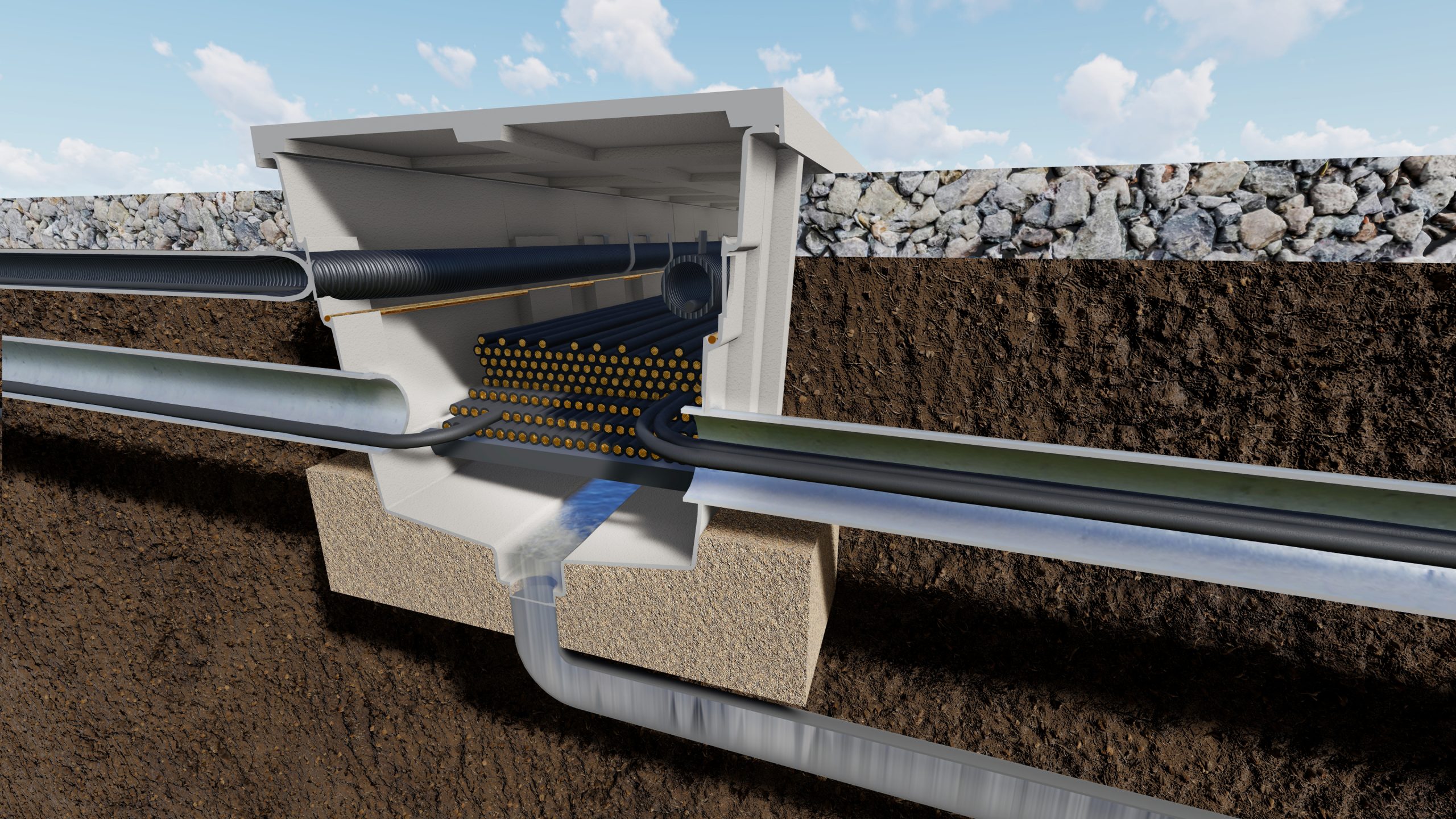

HYDRAULIC TOILET

FIBRAVIT

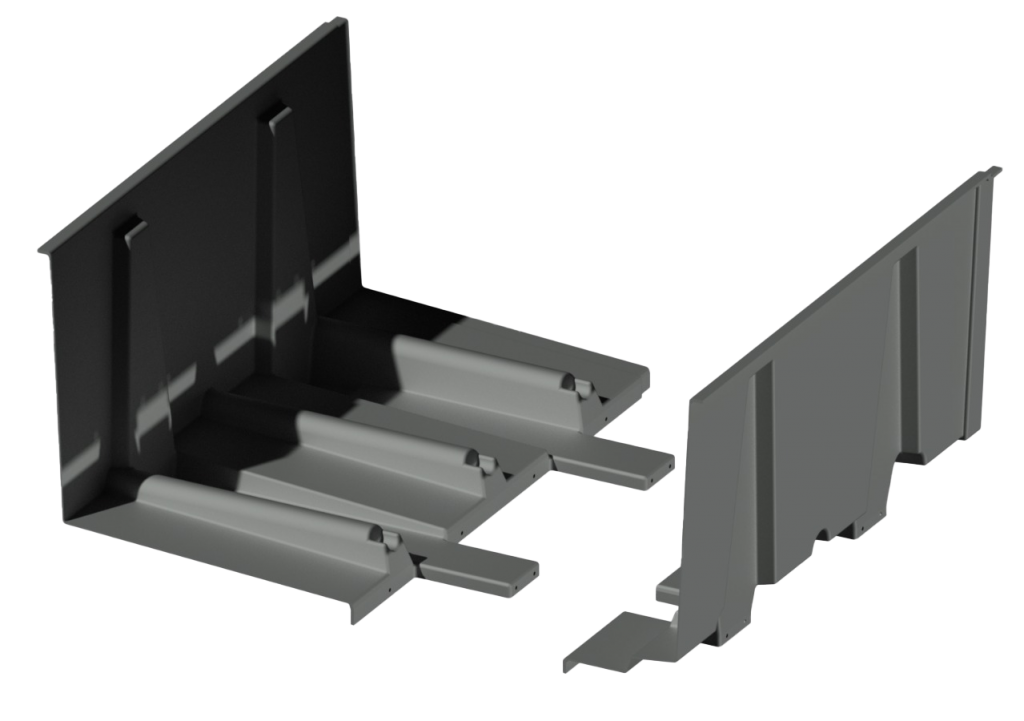

Processes: RTM and Vacuum Forming

A new solution for portable hydraulic toilets. Sustainable processes and materials, low logistics and implementation costs, lightness, beauty and high durability. Plastic components with special hybrid formulations (thermoset and thermoplastic) and using high-performance waste (regranulated).